A real-time assurance system has been developed to significantly improve the cost efficiency of tunnel installations and project delivery times

Costain and i3D robotics have worked with Tunnel Engineering Services and the Manufacturing Technology Center to run successful trials of the digital assurance system, known as Digitally Assured Tunnel Assets – Information System (DATA-IS)

DATA-IS uses automated construction processes and provides real-time quality and safety assurance of tunnelling fit-out services, such as cable wall brackets.

It has been designed to help reduce the cost and time of rework, which has been estimated to account for between 9% and 38% of total project costs in UK construction.

DATA-IS has successfully been trialled alongside ATRIS, an AI enabled, robotic tunnel installation system launched by the consortium earlier this year, which automates the process of bracket installation and reduces the health and safety risks associated with tunnel fit-outs.

Fully automated tunnel installation and assurance

Live data and information from the services installed by ATRIS is used to complete a digital assurance form to technically assure that an individual bracket has been installed successfully.

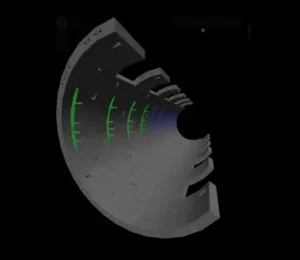

At the same time, this information is uploaded to a digital twin simulation to provide a remote, real-time visual representation of a successful installation.

When combined, ATRIS and DATA-IS offer a fully automated tunnel installation and assurance solution, which can be integrated into modern day construction processes used across different infrastructure projects in road, rail, water and energy.

Costain developed and implemented the digital twin technology and, along with i3D, managed the integration between the ATRIS and DATA-IS systems.

i3D also developed the visualisation software used by ATRIS and optimised its usage for DATA-IS.

The project was overseen by TES, with trials conducted at its special test tunnel facility. MTC led the design and manufacture of the ATRIS end effectors and the robot’s programming.

i3D was awarded funding for the project through the UK government Department for Transport’s First of a Kind 2023 innovation competition, delivered by Innovate UK. As part of the competition, there was a specific focus on driving efficiencies in delivery of the railway’s rail systems, which includes rails, track, signalling and electrics.

‘Potential to transform project efficiency’

Tony Mallichan, digital growth lead for road and rail at Costain, said: “Technical and quality assurance is critical for the installation of mechanical and engineering services in tunnels. But conducting assurance in a tunnelling environment can be a time- and labour-intensive process due to the confined space and limited entry or exit points, and can take many months to execute safely.

“Real-time assurance for capital infrastructure projects has the potential to transform efficiency across a project’s lifecycle, providing greater value-for-money and mitigating risk. With the DATA-IS concept, it’s now a reality. Working closely with our like-minded partners, we have made a real breakthrough – a system that provides technical and quality assurance at the point of installation.

“Working alongside the ATRIS robotics and AI installation system, it is now possible to automate the installation of tunnel services and instantly check the quality and safety of those services against industry benchmarks.”

Dr Richard French, senior systems engineer at i3D, said: “Creating an innovative, robotics-based solution to install tunnel services infrastructure and improve worker safety enabled ATRIS to achieve game-changing success, complete with the successful application of machine learning and AI. The next logical step was to use all the available digital sensory data to help improve inspection and quality assurance, and to deliver paper-free asset handovers – a long-term ambition for the sector.

“Seeing our technology play a central role in meeting this ambition is hugely rewarding. We look forward to seeing its application across a range of industries and robotics and AI become an integral part of the construction process.”