The first on-site 3D printed building in Switzerland has been completed in just 55 hours

Holcim Switzerland worked with PERI 3D Construction to print 6.2m high curved walls over eight days using 60m3 of concrete.

St Gallen-based contractor Kobelt turned to Holcim to develop an innovative 3D printed building to act as its new showroom.

Holcim used a newly developed real concrete mix for the project. It uses less cement and has more strength than the mortars typically used in 3D printed buildings.

The company said the aim was to focus on sustainability and durability, reducing environmental impact while enhancing structural integrity.

Holcim Switzerland partnered with the experienced PERI 3D Construction to assist with the project and used a BOD2 3D construction printer from COBOD, which both are minority shareholders of.

A striking modern design

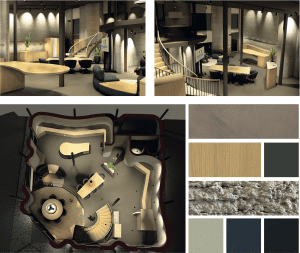

The modern design features fan-shaped steel supports and a wing-shaped roof, which contrasts with the printed concrete and wood-steel elements.

Inside, the 150 sq m showroom combines wood with the concrete printed walls. It is divided into functional zones, including meeting areas, sample displays, a children’s corner, a coffee kitchen and separate meeting room accessed by a rounded staircase.

Seamless flooring and oak-look interior fittings contribute to the modern, uncluttered aesthetic.

Lowering construction CO2 with printable concrete

Kevin Böhlen, project manager at Holcim Switzerland, said: “We printed the showroom in eight printing days with a total of 60 m³ of concrete. There were several challenges, but these learnings will help us improve our workflow for future projects.

“A special thanks to everyone who helped us and supported us. Also, a big thanks to Kobelt AG for their trust in us to print the first onsite building in Switzerland.”

Henrik Lund-Nielsen, founder & general manager of COBOD, added: “We congratulate Holcim on the development of the new 3D printable real concrete. We have been advocating printing with real concrete and not mortars, as printing with mortars leads to use of more cement, higher CO2 emissions and costs.

“We need to lower the CO2 footprint of the construction sector, and this we can achieve by 3D printing material efficient design with real concrete, not mortars.”